The development of fablabs and Do It Yourself, the democratization of 3D printers, wider access to machines, all these things prompt us to wonder about present-day methods of production. While the advantages of using 3D printers, digital milling machines, laser cutters and other digitally guided robots seem numerous—production of nested complex forms, manufacture of pieces on demand, accessibility of production systems, encouragement of short circuits, self-publishing—what level of creative scope and degrees of interaction enable these means of production? Since they give the impression of acting like nothing less than autonomous organisms, the conduct we should adopt regarding them is not evident. For those who want to interact to a greater degree with the “apparatus”11 Pierre-Damien Huyghe, ed., L’art au temps des appareils (Paris: L’Harmattan, 2005). they are using, the question is how to get away from the passive attitude which certain systems engender because they are based on a hermetic, incomprehensible and inaccessible language. It is through different examples, relating in particular to the history of the industrialization of the textile sector, even before the appearance of any computerized system, that models and references can be established. The challenge is to better understand the creative relationship that amateur designers and do-it yourselfers can have with digital machines, once the latter are no longer regarded strictly as a means of execution but rather as parts of an “apparatus” that can be used for working on materials and generating specific forms—in short, as components that incite us to work with them.

Supervising Machines

In the 19th century, a new invention came into being, both in conjunction with and in the wake of the development of the steam engine: the factory. As Jacques Neyrinck, a writer, professor at the École Polytechnique Fédérale in Lausanne and Swiss politician emphasizes, it was in 1850 or thereabouts, in the field of textiles, that the steam engine gradually imposed its rhythm on workers:

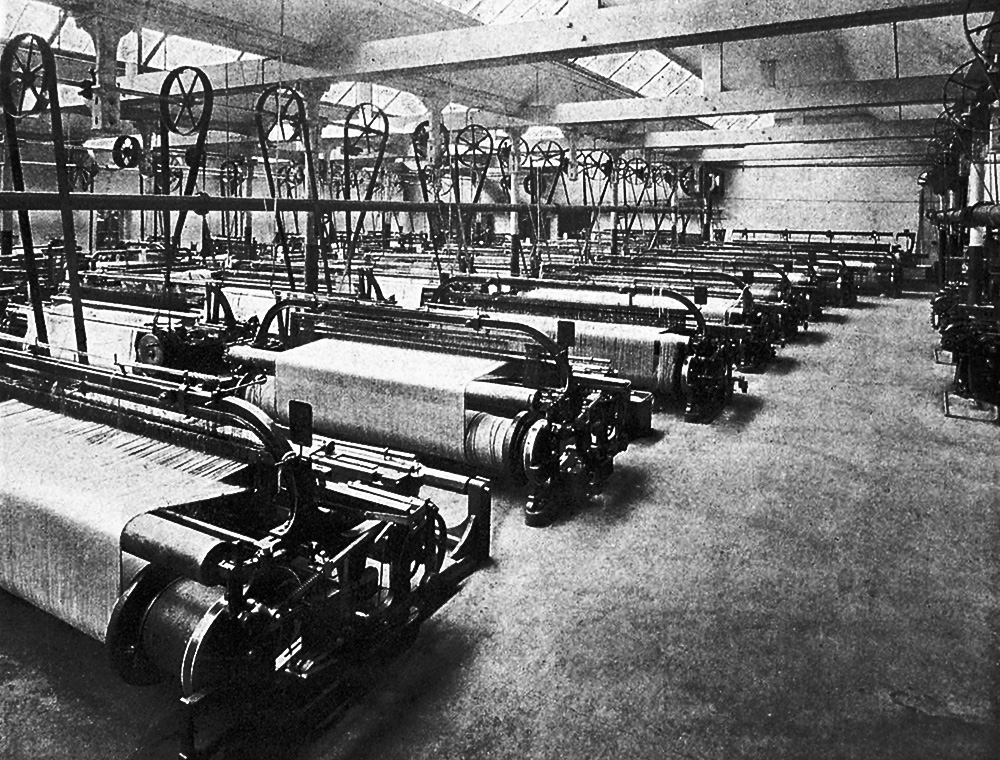

“The 19th-century textile factory was organized around a single steam engine whose movement was transmitted to all the workshops by a set of shafts, pulleys and belts. Once the machine was set in motion, each worker had to adapt to its pace and in a way become a semi-intelligent organ of that huge piece of machinery, made of both steel and flesh, steam and sweat. To use the hallowed words, matter emerged from that factory ennobled, and man degraded.”22 Jacques Neyrinck, Le huitième jour de la création, introduction à l’entropologie (Lausanne: Presses Polytechniques Romandes, 1986), 173.

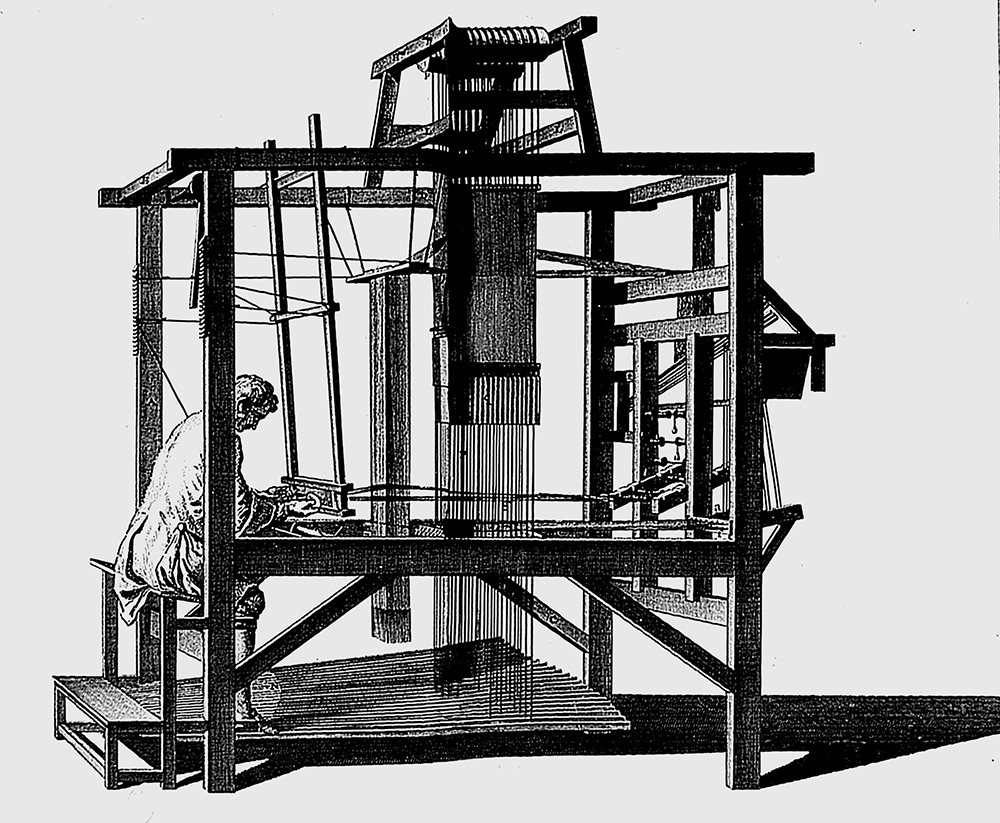

The development of this new technical ensemble literally defined the worker by the tools of his trade. As a result, the type of initial relationship to the machine was seen as something almost carnal and organic,  emphasizing more than ever before the relationship between an artisan-weaver and their loom. For by becoming one with the machine, the worker enjoyed a direct relationship with what they were making at the same time as they submitted to its logic and its pace. Before long this paradoxical proximity would be challenged by a gradual process of mechanized and automated manufacture. The consequence of this development was the more or less swift disappearance of human beings from workshops.

emphasizing more than ever before the relationship between an artisan-weaver and their loom. For by becoming one with the machine, the worker enjoyed a direct relationship with what they were making at the same time as they submitted to its logic and its pace. Before long this paradoxical proximity would be challenged by a gradual process of mechanized and automated manufacture. The consequence of this development was the more or less swift disappearance of human beings from workshops.  While the machine freed the human being from laborious tasks, it excluded him from the production process, which led to a weakening of his capacity for action. This logic not only affected the social dimension of labor, but also reduced the worker’s creative share, along with his involvement, his inventions, and his discoveries. While the machine can be accused of many ills (pollution, unemployment, alienation of the human being, unfair competition, etc.), it is nevertheless not in this sense that Pedro Rioux de Maillou saw the relationship between the decorative arts and machines. As a contributor to the Revue des Arts Décoratifs and an ardent champion of a democratic form of mechanical production, he was far from contrasting the worker with the machine, and, as far back as 1882, he was pleading for “an improvement of machines with a view to a more artistic production, rather than their replacement.”33 Jérémie Cerman, “Pedro Rioux de Maillou, Les Arts décoratifs et les machines, 1895,” in Neil McWilliam, Catherine Méneux and Julie Ramos, ed., L’Art social de la Révolution à la Grande Guerre. Anthologie de textes sources (Paris: INHA, 2014).

While the machine freed the human being from laborious tasks, it excluded him from the production process, which led to a weakening of his capacity for action. This logic not only affected the social dimension of labor, but also reduced the worker’s creative share, along with his involvement, his inventions, and his discoveries. While the machine can be accused of many ills (pollution, unemployment, alienation of the human being, unfair competition, etc.), it is nevertheless not in this sense that Pedro Rioux de Maillou saw the relationship between the decorative arts and machines. As a contributor to the Revue des Arts Décoratifs and an ardent champion of a democratic form of mechanical production, he was far from contrasting the worker with the machine, and, as far back as 1882, he was pleading for “an improvement of machines with a view to a more artistic production, rather than their replacement.”33 Jérémie Cerman, “Pedro Rioux de Maillou, Les Arts décoratifs et les machines, 1895,” in Neil McWilliam, Catherine Méneux and Julie Ramos, ed., L’Art social de la Révolution à la Grande Guerre. Anthologie de textes sources (Paris: INHA, 2014).

“The man is sitting at his loom—a Jacquard, with the different colored silks arranged within arm’s reach, in the planned order of the pattern of the brocade, thanks to the perforated cartoons invented by Jacquard, which automatically follow each another at the top of the loom; the brocade will be mechanically designed as the weft moves slowly back and forth. But the worker does not remain an impassive onlooker of the artistic weave thus produced. They do not limit themselves to adjusting the machine’s movement, and acting simply as a mechanic. Their supervision is different; in a way, their actions are of a far a more direct and intimate nature with the fabric to be brocaded. Firstly, the combination and timely succession of the variously colored silks is their work. The proof of this is that the brocade will be as good as the worker, over and above the matter of sheer care and the habits created by manual work. The same goes for the finished result, the appropriated goods, and the success of the brocade’s design. The taste of the operator even makes itself felt. […] Far from the machine mechanizing the worker, on the contrary, the worker must interact with the loom like a rider who is master of their mount, as one who is capable of transmitting to it all their wishes, even their desires, and impressions. So, within certain proportions, the worker must be a draughtsperson and colorist, so that his brocade will have all its charm in terms of design and color. Consequently in this communion of the feeling, knowing, wanting human, who imprints their feeling, knowledge and desire on the machine—in his hand, at the service of his inspiration—there is room for taste, for active taste, acting and producing, which is to say room for art, in the esthetic sense of the word.”44 Pedro Rioux de Maillou, “Les arts décoratifs et les machines,” Revue des Arts Décoratifs (Paris: Union Centrale des Arts Décoratifs, 1894–1895), 271–272.

In this excerpt, Pedro Rioux de Maillou thus depicts a relation to the machine that is not necessarily and systematically the cause of a deterioration of the human condition of workers even though it may involve automated procedures. On the contrary, he underwrites a convergence between the machine’s mechanical possibilities and the artist’s enlightened sense of things. Unlike the “modern industry” of Karl Marx,55 See chapter 15: “Machinery and Modern Industry” in Karl Marx, Capital: A Critique of Political Economy (London: Penguin Books, 1990). the worker is not interchangeable: the machine calls for an intervention other than the purely mechanic, it involves the sense and taste of the person operating it.

Today, new factories with their rows of 3D printers, all identical and connected to a general server or an integrated digital control, are pursuing this logic involving the automation of the production line, and giving rise to the elimination, no more no less, of human beings from factories, or at the very least their wholesale disappearance, leaving just a handful of specialists to deal with the control and upkeep of the means of production.  This development of the environment and means of production, which is part of a logic of “industrial overgrowth,” based on automation, a quest for profitability, and an increase in production rates, limits, even prevents the worker’s involvement in his labor.66 Ibid. As sociologist Rudi Supek observes:

This development of the environment and means of production, which is part of a logic of “industrial overgrowth,” based on automation, a quest for profitability, and an increase in production rates, limits, even prevents the worker’s involvement in his labor.66 Ibid. As sociologist Rudi Supek observes:

“There is no doubt that the power of human labor, and the physical strength of the worker are truly becoming a ‘wretched base’ [Karl Marx], when we compare them to the power of production of modern industry. What is essential from a sociological and technological viewpoint, is that man stands, or ‘positions himself alongside the production process that he has dominated’, fulfilling, in production, the sole function of the supervisor or inspector; he is no longer a source of energy or labor, but rather a project designer […].”77 Rudi Supek, “Karl Marx à l’époque de l’automation,” in L’homme et la société 3 (Paris: L’Harmattan, 1967), 107.

This supervisory role is also mentioned by the philosopher Gilbert Simondon, when he refers to the relationship of the machine regarding the notion of progress, a link which changes with the replacement of human and animal forces by machines and “the birth of complete technical individuals”:99 Ibid., 115.

“The progress made in the 18th century left the human individual intact, because the human individual remained a technical individual, in the midst of his tools, of which he was both the hub and the operator. […] The progress made in the 18th century was a progress felt by the individual in terms of the strength, speed, and precision of his gestures. The progress made in the 19th century could no longer be felt by the individual, because he was no longer centralized by it as a nexus of control and perception, within the adapted action. The individual becomes a mere onlooker of the results of the way machines work, or someone in charge of the organization of the technical complexes that set machines in motion.”1010 Ibid., 115–116.

With regards to this varied evidence, we might well wonder if, at the end of the day, fablabs and, more generally, the artisanal spirit projected by various DIY enthusiasts, are not a response to an unconscious need felt by designers to create a proximity, even a sense of closeness with the production apparatus, that has been adversely affected by a dominant industrial logic.

Encoding Machines

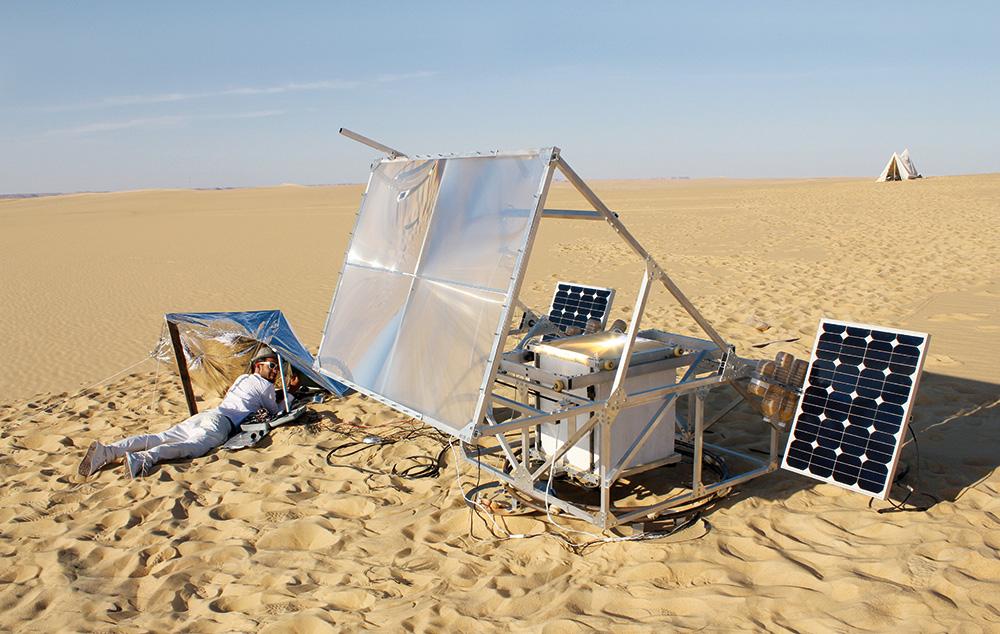

The issue of integrating automated processes within different workstations is not raised solely by designers and workers, but also by those who manufacture and improve machines. The esthetic sense of the user of a machine is one thing, but it is still necessary for the machine to be set up to accommodate this sensibility. It is, incidentally, not surprising that, for the past ten years or so, several designers—from Katharina Mischer and Thomas Traxler and The Idea of a Tree (2008), to François Brument’s What’s Wind Drawing? (2010), the Unfold Design Studio’s Electronic Artisan (2010), Markus Kayser and his Solar Sinter (2011),

to François Brument’s What’s Wind Drawing? (2010), the Unfold Design Studio’s Electronic Artisan (2010), Markus Kayser and his Solar Sinter (2011), or Phil Cuttance and his mechanical Faceture machine (2012)—have set out to invent their own mechanical and/or digital machine tools, suggesting, it just so happens, that esthetic and perceptive qualities are being insufficiently taken into account by current inventors of digitally controlled machines and robots. Fablabs and makerspaces are probably the most consummate manifestations of people’s desire to not be told what they have to do by ready-to-use machines. These two types of places represent new manufacturing spaces, where direct interaction with tools is possible in a non-hierarchical way (with each person determining what they do) and from the standpoint of knowledge sharing, in contrast with the models of Taylorism and Fordism. In this sense, fablabs may be thought of as an alternative to industrial automation, favorable to personal and collective fulfilment. Within them, it is not a matter of just imagining an object made by machines, but also of thinking about ways of working, and of designing objects with machines.

or Phil Cuttance and his mechanical Faceture machine (2012)—have set out to invent their own mechanical and/or digital machine tools, suggesting, it just so happens, that esthetic and perceptive qualities are being insufficiently taken into account by current inventors of digitally controlled machines and robots. Fablabs and makerspaces are probably the most consummate manifestations of people’s desire to not be told what they have to do by ready-to-use machines. These two types of places represent new manufacturing spaces, where direct interaction with tools is possible in a non-hierarchical way (with each person determining what they do) and from the standpoint of knowledge sharing, in contrast with the models of Taylorism and Fordism. In this sense, fablabs may be thought of as an alternative to industrial automation, favorable to personal and collective fulfilment. Within them, it is not a matter of just imagining an object made by machines, but also of thinking about ways of working, and of designing objects with machines.

From this standpoint, “encouraging the fulfilment of the creative possibilities specific to each individual”1212 Supek, op. cit., 112. might turn out to be a fundamental challenge. Consequently, the designer might be Simondon’s “machine man,” who is not totally removed from what he is making—neither just an organizer of the production force, nor an engineer1313 Gilbert Simondon , op. cit., 117.—but the person who sets machines in motion, which is to say the person who esthetically summons them with regard to what is being produced. Walter Benjamin speaks about the cameraman “deeply penetrat[ing] the fabric of given reality,” and “operator” with an emphasis on the Latin root of the word, comparing him to the surgeon who “proceeds to carry out an operation on the body,” in contrast with the magician who keeps his distance.1414 Walter Benjamin, “L’œuvre d’art à l’époque de sa reproduction mécanisée,” in Écrits français (Paris: Gallimard, 2003), 206.

First published in 1936.

Technical Improvements and Creative Freedom

Having a creative relationship with machines is not easy, all the more so because it is often hampered by the machines themselves and by the productive structure of which they are a part. As Anni Albers, a weaver who was trained at the Bauhaus from 1922 on, aptly observes:

“[While] machines reduce the boredom of repetition, and repetitive tasks, on the other hand, they limit the interplay of imagination in the preliminary phase of production. […] No variation, she says, is possible once the production process is under way […]. We see for example that, for a weaver, the foot loom allows for a far greater variety of results than an automatic mechanical loom because, as Luther Hooper puts it, with ‘each stage of mechanical improvement of the loom, as moreover is the case with all machines in varying degrees, the weaver’s freedom and his or her control of the conception of their work is reduced.’”1515 Anni Albers, “Work with Material,” Black Mountain College Bulletin 5 (Asheville: University of North Carolina, 1938).

How then are we to act so that the improvement of machinery does not mean a limitation of creative possibilities and the use of machines, but rather, even broader possibilities and uses? By adopting a “creative logic,” where the challenge is not to improve production output but rather to diversify what is obtained, esthetic, structural, functional and ecological associations to what is being produced can develop.

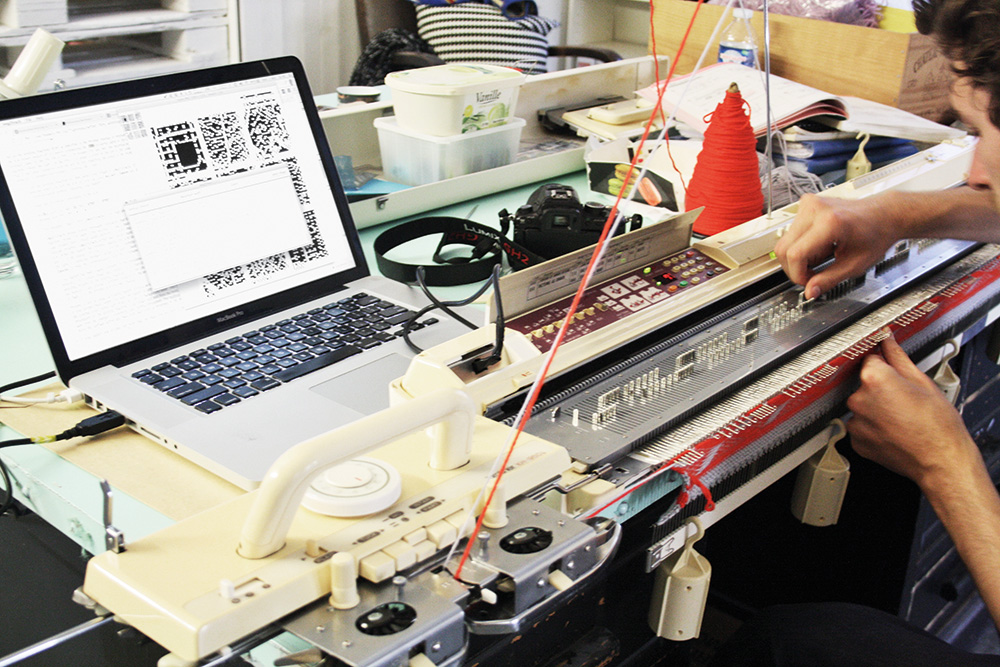

So the machine is called upon due to its potential and capacity to give form to matter, summon it, constrain it, and test its flexibility, structure and tactility. The Tricodeur project (2014–2015), based on the meeting between knit design and programming, involves the hacking of an electronic knitting machine.1616 Created in 2014–2015 by the 2Roqs studio and designer Louis Eveillard in partnership with the association Sew&Laine. Voir/See: http://b-o.fr/tricodeur Once “hacked,” this knitting machine, connected to a computer, led to the creation of motifs created with the help of digital algorithms (abstract and personal data visualization media) and the design of a specific font, Tricofont, by Emilie Coquard for weaving small characters and letters.

based on the meeting between knit design and programming, involves the hacking of an electronic knitting machine.1616 Created in 2014–2015 by the 2Roqs studio and designer Louis Eveillard in partnership with the association Sew&Laine. Voir/See: http://b-o.fr/tricodeur Once “hacked,” this knitting machine, connected to a computer, led to the creation of motifs created with the help of digital algorithms (abstract and personal data visualization media) and the design of a specific font, Tricofont, by Emilie Coquard for weaving small characters and letters.

Accessible by a free download on GitHub,1717 Tricodeur Workshop, prepared and organized by Louis Eveillard from October 10–12, 2014at Processing Bordeaux.

Voir/See: http://b-o.fr/tricodeur2 the files which are the source of these productions (under the free Creative Commons CC BY-SA license) are open to reproduction and processing. The Tricodeur—which is not unconnected to the history of textiles (i.e. Jacquard looms with their perforated cards), of computer science (in reference to the analytical machine conceived of by mathematician Charles Babbage in 1843), and the Arts and Crafts tradition (by combining social dimension and artistic production)—shows how the transformation of a machine within a system of creative logic may give rise to specific productions for which the esthetic dimensions (knit work), social dimensions (collaborative projects in the form of residencies, workshops and studios) and functional dimensions (differing end purposes: typography, data visualization, experience sharing, artistic output, etc.) lie at the heart of what concerns us. This proposition, which encourages a direct relation to tools involving at once computer, electronic and esthetic skills, illustrates the fact that programming work does not necessarily mean that the creator becomes removed from the machine, but also that the creatively controlled digital machine can produce promising results. An understanding of the way the apparatus works, the identification of its esthetic and productive potential, and the possibilities of intervention and coding enable enough modifications to provide the possibility of creating and testing numerous variations.

The Hand Does not do Everything in the Relationship with the Machine

In this context, a spirit of craftsmanship comes to the fore, not because the hand is at work, but because exploratory work with the machine involving the workshop takes place. So, unlike the craftsman’s classic association with his tools, the hand is not the sole requirement for working with machines, nor the element that, in the first instance, esthetically speaking, determines the output. Although the hand is still indispensable in many stages of the design and making of the product—typing on the keyboard, handling products, and sometimes dealing with finishes—it cannot be regarded as “primary.” If such an assertion were already effective in the field of industrial production and design, it introduces a profound break with traditional craftsmanship, regarded as the expression of a manual making. So we must look elsewhere for a human presence than the hand. The history of design has shown that many designers have maintained close associations with factories, producers, craftspeople, tools, machines and industries, but without nevertheless directly manufacturing the pieces they designed. Most of the time, a collaborative situation with specialized workers and craftsmen was successfully initiated, in such a way that, through the observation and understanding of production methods, designers have been able, not only to alter their way of thinking about forms and designing objects, but also to get workers to modify and develop machine tools with respect to the goal desired. At a lecture entitled “Not Made by Human Hands/Non fait de main d’homme,”1818 Patricia Falguières, “Non fait de main d’homme,” lecture at ENSAD, Paris (2013). Voir/See:http://b-o.fr/nonfait historian Patricia Falguières pointed out that the particular feature of human factories does not have to do only with the “hand” that made, but with the spirit—the concetto—that moves them. The demonstration of a particularly human intelligence does not necessarily lead to a depreciation of the hand, and helps us to get beyond the idea that the machine could not give rise to beautiful and sensitive works that are deeply human. The idea does indeed consist in understanding how a factory with machines is possible, and thinking about how humanity can exist, and manifest itself through this, as it were, “demanualized” relationship, or, to put it differently, one that is not fundamentally manual.

In Support of a Creative Relationship with Machines

Nowadays, the question of an imagination at work in tandem with the machine seems to be being called into question by the development of ready-to-use digital machines accentuating a separation between design work, situated upstream, and production, downstream. Due to the coding necessary to make them work and the programming required to run and control them, computer science and digital machines seem to be creating an increased distance from the person who deals with them, thereby affecting all “direct experience”1919 Albers, op. cit. with machines. The fact is that a certain rapport between the person who designs and the person who programs the machine can be observed and asserted. As a result, making do with machines hangs on at least two conditions: on the one hand it presupposes that a specific spirit is at work, underpinned by an attentiveness and a technical sensibility that encompasses certain esthetic concerns, and, on the other, that machines enable possible transformations and adaptations (assembly, dismantlement, suitability, adjustment, open programming, disconnected uses). Acting directly upon machines in order to encourage something reciprocal with regard to tests and experiments turns out to be vital if an observation of results and an understanding of phenomena can take place. They must be frequently testable and it should be possible to interrupt and resume their operation as desired. As a corollary, this implies that the engineers in charge of designing them must diversify their approaches and even the actual end purposes of their designs in order to get away from a logic of repetitive production governed solely by a quest for performance. To this end, collaborations between designers and engineers must be fruitful in order to modify machine designs, so that they become nothing less than “machine-tools” with which one can work.